Pipe elbows are crucial parts in plumbing setups. They allow smooth changes in the path of pipelines. These fittings work well for homes, businesses, or factories. They ensure liquids flow efficiently. This article discusses what pipe elbows are, their types, materials, and roles. It also covers other fittings and why Vicast is a dependable source for top-notch pipe fittings.

What Are Pipe Elbows in Plumbing Systems?

The following is an introduction about pipe elbows.

Definition and Purpose of Pipe Elbows

Pipe elbows are fittings that join pipes at an angle. They help the pipeline shift direction. They guide liquids or gases around corners or obstacles. This keeps the flow steady. Pipe elbows come in angles like 90° or 45°. They are vital in plumbing, heating, and cooling systems, or industrial setups. Their main job is to keep the flow smooth while fitting around structures.

Common Materials Used for Pipe Elbows

Pipe elbows are made from various materials. Each suits specific needs. The material choice affects strength, rust resistance, and how well it works with the liquid or gas. Common materials include:

Stainless Steel: It resists rust and works well in tough settings like chemical plants.

Carbon Steel: It is sturdy and affordable for high-pressure uses.

PVC (Polyvinyl Chloride): It is light and resists rust, often used in home plumbing.

Copper: It is strong and conducts heat well, great for water lines.

Ductile Iron: It is tough and flexible, used in heavy-duty systems.

| Material | Key Features | Common Uses |

| Stainless Steel | Rust-resistant, sturdy | Chemical plants, ocean systems |

| Carbon Steel | Strong, budget-friendly | Oil and gas lines |

| PVC | Light, cheap | Home plumbing |

| Copper | Heat-conductive, reliable | Water supply lines |

| Ductile Iron | Tough, bendable | Factory water systems |

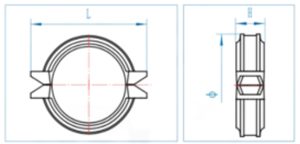

Types of Pipe Elbows Based on Angle and Application

Pipe elbows vary by angle and connection type. Each fits specific plumbing tasks. For example, 90° elbows create sharp turns. Meanwhile, 45° elbows make gentler shifts. Long-radius elbows have a wider curve. They reduce friction in fast-flowing systems. Short-radius elbows are smaller. They fit in tight spaces but cause more flow resistance. Grooved elbows allow quick setup in grooved pipe fitting systems.

How Do Pipe Elbows Work in Plumbing Systems?

Knowing this can help you understand better.

The Role of Pipe Elbows in Redirecting Flow

Pipe elbows guide liquids or gases around corners. They do this without harming the system’s strength. For instance, in a home, a 90° elbow might link a vertical pipe to a horizontal one. This directs water to a tap. The elbow ensures the flow stays smooth. It also prevents leaks.

Importance of Pipe Elbows in Managing Pressure and Flow Dynamics

Pipe elbows are key to controlling pressure and flow. Poorly chosen or badly installed elbows can cause turbulence. This leads to pressure drops or system issues. For example, long-radius elbows lower friction and turbulence. They work well in high-pressure setups. Properly picked elbows also stop cavitation. This is when quick pressure changes create vapor bubbles. These bubbles can collapse and damage pipes.

Applications of Pipe Elbows in Different Plumbing Scenarios

Pipe elbows are flexible. They are used in many areas. In homes, they connect water lines in bathrooms or kitchens. In factories, they handle liquids in chemical, oil, or gas lines. They also guide airflow in heating and cooling systems. In fire protection, elbows direct water in sprinkler setups. In farming, they help water flow through irrigation networks.

What Other Essential Pipe Fittings Are Used Alongside Pipe Elbows?

Besides elbows, tees and cross fittings are important in plumbing. Tees have a T shape. They connect three pipes. This lets the flow split in different directions. They are common in water systems. Cross fittings join four pipes at one point. They are used in complex setups, like in factories. Check out Vicast’s grooved pipe fitting tees for dependable options.

Comparing Pipe Elbows, Tees, and Cross Fittings

| Fitting Type | Shape | Function | Common Use Case |

| Pipe Elbow | Curved (90° or 45°) | Shifts flow direction | Moving around corners |

| Tee | T-shaped | Splits flow into two paths | Water distribution |

| Cross | Cross-shaped | Splits flow into three paths | Complex factory systems |

Each fitting has a unique role. However, elbows are often used most due to their job in changing direction.

Why Choose Vicast as a Reliable Supplier for Pipe Fitting Couplings?

Vicast is a very reliable supplier. Here are some information about vicast.

An Introduction to Vicast’s Expertise and Product Range

Vicast is a pinnacle maker and company of brilliant pipe fittings. They focal point on grooved fittings, couplings, and associated parts. With years of skill, Vicast affords clever options for plumbing, furnace safety, and industrial uses. Their merchandise consist of sturdy elbows, tees, and grooved couplings. These meet global standards and serve many industries worldwide.

Benefits of Choosing Vicast for High-Quality Pipe Fittings

Choosing Vicast has many perks. Their products are made with care. This ensures they are strong and reliable. They offer a wide range of items, from grooved elbows to mechanical tees. Their fittings meet strict industry rules, ensuring safety and performance. Vicast’s team provides expert advice to pick the right fittings. Plus, their prices are fair for high-quality items. For questions or custom needs, contact Vicast.

Conclusion

Pipe elbows are essential in plumbing systems. They guide flow around corners while keeping pressure steady. They come in various materials and angles. This makes them suitable for homes, factories, and more. Paired with fittings like tees and crosses, they make certain easy pipeline work. By selecting a relied on provider like Vicast, you get gorgeous pipe fittings. These are tailor-made to your desires and make certain lasting performance.

FAQs About Pipe Elbows and Plumbing Systems

What are the key factors to consider when selecting a pipe elbow?

When picking a pipe elbow, think about a few things. First, ensure the material matches the liquid or gas. Next, choose the right angle, like 90° or 45°, for the pipeline’s path. Also, check if the elbow can handle the system’s pressure. Finally, match the elbow to the task, such as home or factory use.

How do I determine the appropriate angle for a pipe elbow?

The angle depends on the pipeline’s layout and flow needs. A 90° elbow works for sharp turns. A 45° elbow is better for gentle shifts to reduce flow resistance. Talk to a supplier like Vicast. They can study your system and suggest the best angle.

Can pipe elbows be used with all types of plumbing materials?

Pipe elbows are adaptable but must match the pipe material. For example, copper elbows work with copper pipes. PVC elbows suit PVC systems. Always check material compatibility to avoid rust or leaks. Vicast’s product range includes fittings for many materials.